Shangqiu Jinpeng Industrial Co., Ltd.

csr1@pyrolysis-machine.com

+86-15824739999

Shangqiu Jinpeng Industrial Co., Ltd.

csr1@pyrolysis-machine.com

+86-15824739999

Continuous waste plastic pyrolysis equipment

Waste rubber and plastic oil refining equipment uses to decompose various waste rubbers and plastic products into fuel oil and carbon black by high temperature biomass; The raw materials are cheap and easy to obtain, the refining process is simple and automated, and the resulting products, fuel oil and carbon black, can be sold directly for profit.

.jpg)

Usage

All kinds of waste rubber, tires, plastic products are decomposed into fuel oil, carbon black and steel wire by high temperature pyrolysis.

Oil yield

All kinds of waste rubber, tires, plastic products are decomposed into fuel oil, carbon black and steel wire by high temperature pyrolysis.

|

NO. |

Raw material |

Oil yield |

|

1 |

HDPE |

≧70% |

|

2 |

LDPE |

30% -50% |

|

3 |

PVC |

20%-30% |

|

4 |

工程塑料 |

40% |

|

Product |

Use |

|

|

Fuel oil |

Widely used in steel plants, ceramic factories and other industrial enterprises or chemical enterprises as well as hotels, restaurants, etc. as fuel combustion, but also can be used for heavy oil generators to generate electricity. |

|

|

Carbon black |

Coarse carbon black can be used as raw materials for building bricks, and can also be deeply processed into industrial carbon black, semi-reinforced carbon black, pigmented carbon black, and its application is extensive. |

|

|

Sync gas |

Can be used or collected as fuel during the production of the equipment. |

|

Jinpeng Industrial Waste Plastic pyrolysis Equipment:

In order to better adapt to the more stringent environmental protection requirements of developed countries in Europe and the United States than in developing countries, Jinpeng Industry launched a "continuous biomass pyrolysis equipment", high-temperature decomposition of waste plastics, through different physical temperature segments, to achieve water, oil and gas, slag separation, oil and gas through the cooling equipment to achieve recovery, while waste emissions meet national standards, and the entire production process is environmentally friendly and pollution-free.

Waste plastic pyrolysis equipment: waste plastic collection is decomposed into fuel oil at high temperature, carbon black.

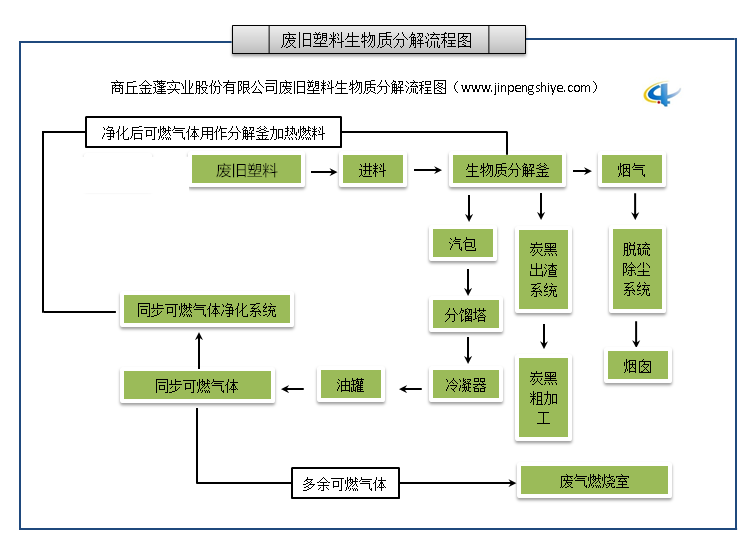

Equipment biomass pyrolysis flow chart:

Flow chart

The waste plastic is continuously fed through the automatic feeder to the reactor, catalytic heating, and the oil vapor is distillated.

The oil and gas passes through the steam drum buffer and release pressure, enters the condenser, liquefies the part, and condenses into fuel oil.

The non-liquefiable part, that is, the synchronous gas is removed by the synchronous gas purification system to remove the acid gas and dust, and then poked into the combustion chamber through the combustible gas recovery system for fuel use; A small amount of excess flammable gas is introduced into the excess gas combustion chamber for combustion or collection.

The soot generated by the combustion process is removed by the desulfurization dust removal system to remove the acid gas and dust, and is discharged after meeting the national environmental protection standards.

Carbon black is automatically output during the slagging process through a closed slag discharging system.

Equipment features: